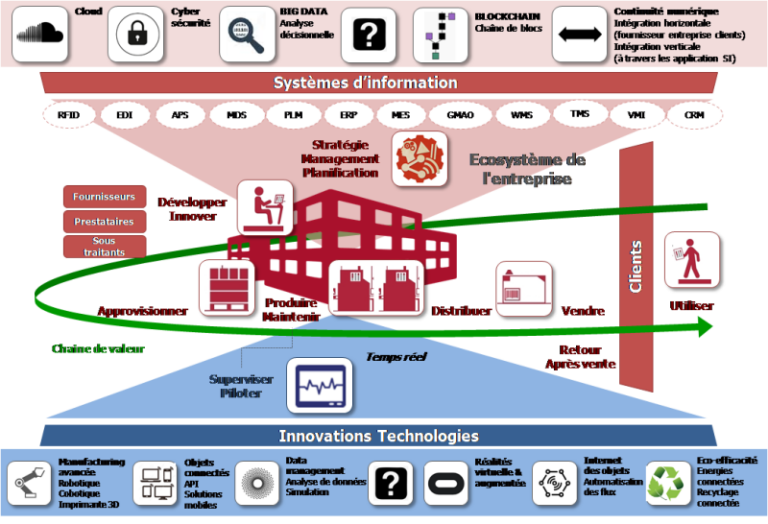

Over the past few years, the media have been talking a lot about the transformation and future of industry known as Industry 4.0. Beyond the concept, this is first and foremost testimony to the transition to digitization of industrial processes and the integration of new technologies to boost productivity, significantly reduce costs and improve product and process quality. Let us take you into Industry 4.0.

Industry 4.0: a fast-growing reality for developing competitiveness

The rapid and combined evolution of technologies and information systems are leading you, as a manager, to ask questions about their real or supposed contributions, and about their integration into the company.

Your customers, suppliers and employees are asking you about their expectations, concerns and solutions.

Industry 4.0 offers immense scope for progress across all business activities and functions. Many experts speak of 4th industrial revolution.

This field is so abundant and diversified that it is difficult to apprehend, to evaluate in terms of stakes, and to implement effectively for each company.

Our conviction: the company that makes a proactive commitment to Industry 4.0 offers itself

- Powerful levers for improving operational performance (safety, environment, quality, services, costs) across the entire value chain, both internally and in its ecosystem

- The opportunity to enrich its value proposition by offering more personalized and interactive services

- Innovative ways to develop strategic agility and competitiveness.

Moving towards Industry 4.0 means adding value to the operational chain by bringing together the virtual and the physical in innovative ways.

What are the benefits of Industry 4.0?

Industry 4.0 applications are extremely varied in terms of cost and complexity of implementation, depending on defined processes.

- Eliminate paper and move towards greater digitization - Digitize your business documents (work instructions, forms, purchase orders, packing slips, product specifications, etc.) to save time and money, and reduce errors caused by erroneous or out-of-date data.

- Monitor and control machines and equipment in real time - Install wireless sensors (Internet of Things) on machines and equipment to monitor production and collect data in real time. The aim: to accurately track production, spot and correct problems, and make more informed strategic decisions.

- Introduce intelligent processes - Use machines that can analyze their own data to predict when they need servicing; some can even schedule an appointment with a technician. Advanced control technologies assess quality in real time during production, and intervene when defects need to be corrected.

- Optimize processes - Explore data with advanced analysis software to identify the best production and maintenance scenarios, and use these to improve production and optimize asset utilization.

- Embrace 3D printing - Use 3D printers to rapidly produce prototypes, fabricate complex shapes and create highly customized products to your customers' specifications.

- Connect products to the Internet - Equip products with sensors to monitor their use, alerting your customers when it's time for maintenance and warning them of any problems. Intelligent products also make it possible to add services based on usage, to move to a product-as-a-service business model, or to develop innovative new products.

How can we help you move towards Industry 4.0?

- DEFINE your own vision of the factory of the future

- IDENTIFY the most relevant tools in the value chain

- BUILD a controlled investment plan

- ORCHESTRATE deployment to meet your business objectives

Further information

5 minutes to understand why you need to master your value chain

Like Rome, the understanding of value creation didn't happen overnight... In fact, for almost 200 years, companies have been creating value for their customers.

Customer path - Processes - Risks & Internal Control: improving, securing and transforming the company

Due to a low level of maturity (the most favorable case) or a logic of territories and organizational silos (an unfortunately frequent situation), linking the

How can process-based performance meet the company's strategic challenges?

iQo is one of France's leading players in process-driven organizational transformation. Our consultants support the operational transformation of organizations, helping them to